Meet Our Customer

Unlocking the Holy Grail of Robotic Fulfillment*

Industry

Application

Results

Overview

Our customer is a Fortune 500 Robotics OEM with a 150-year reputation for transforming the supply chain and logistics industries through technological innovation.

Three facets of the evolving logistics industry pointed to a critical need for new robotic solutions to aid with the task of unloading shipping pallets (known as depalletizing):

- Robotic parcel picking is significantly harder than before. The diversity of parcel types has exploded due to the growth of direct-to-consumer and online businesses. Logistics facilities are expected to handle a wider multitude of boxes, from more suppliers, without losing throughput velocity. Mixed SKU depalletizing (the task of unloading a pallet of non-uniform parcels) has increasingly emerged as a challenge.

- Humans are not well-suited for this job. Manual parcel picking is difficult, injury-prone, and monotonous. High turnover in these roles, combined with broader-base labor shortages, saddles warehouse owners with a huge operational burden and continuity risk that jeopardizes throughput.

- Traditional robots weren’t cutting it. Mixed SKU depalletizing is the holy grail of robotic fulfillment, and for good reason. Traditional robots are mainly focused on simple, repetitive, and highly predictable tasks – like moving an endless stream of the exact same box type and size. They struggle to identify boxes of diverse color, dimension, weight, and other characteristics.

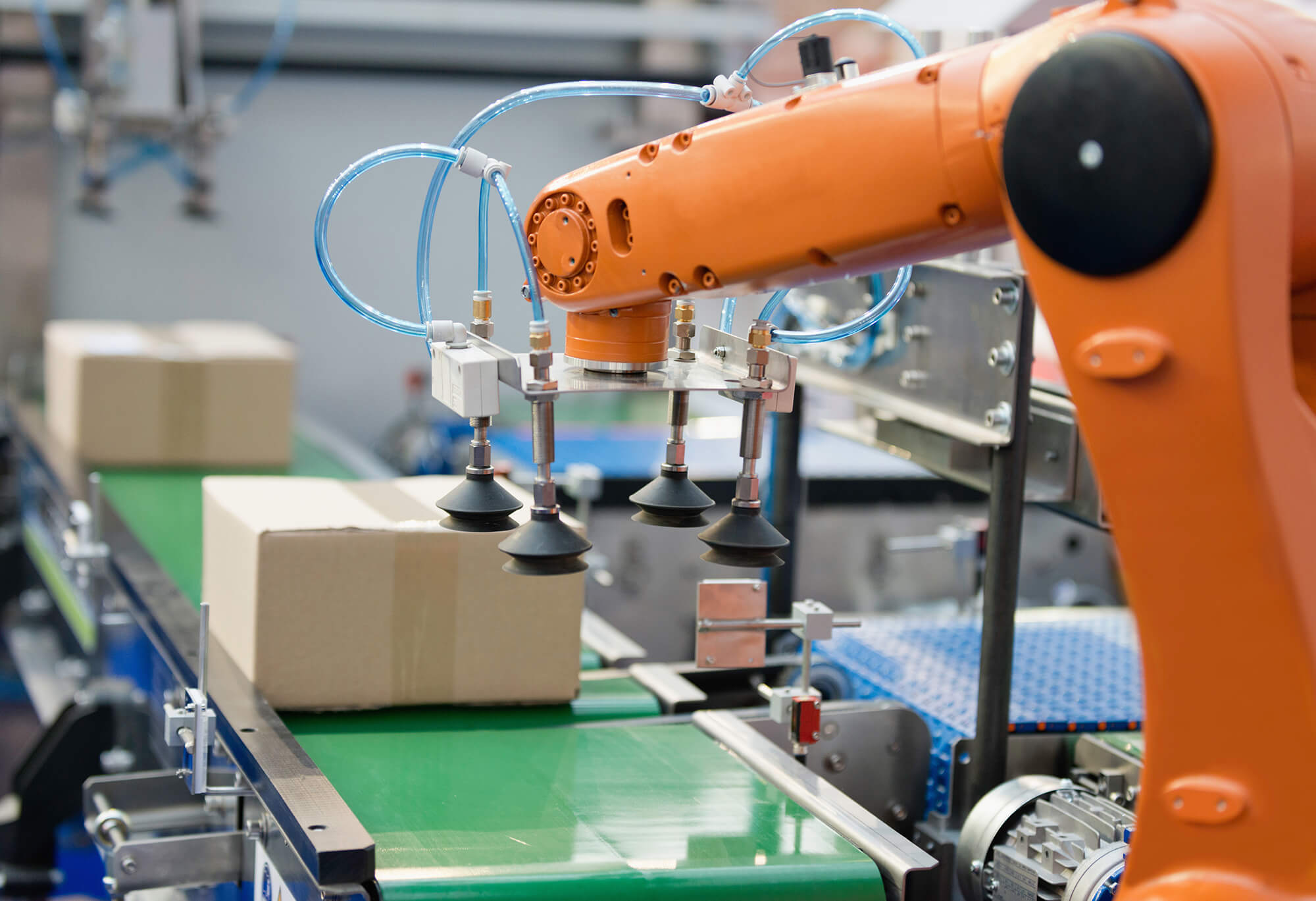

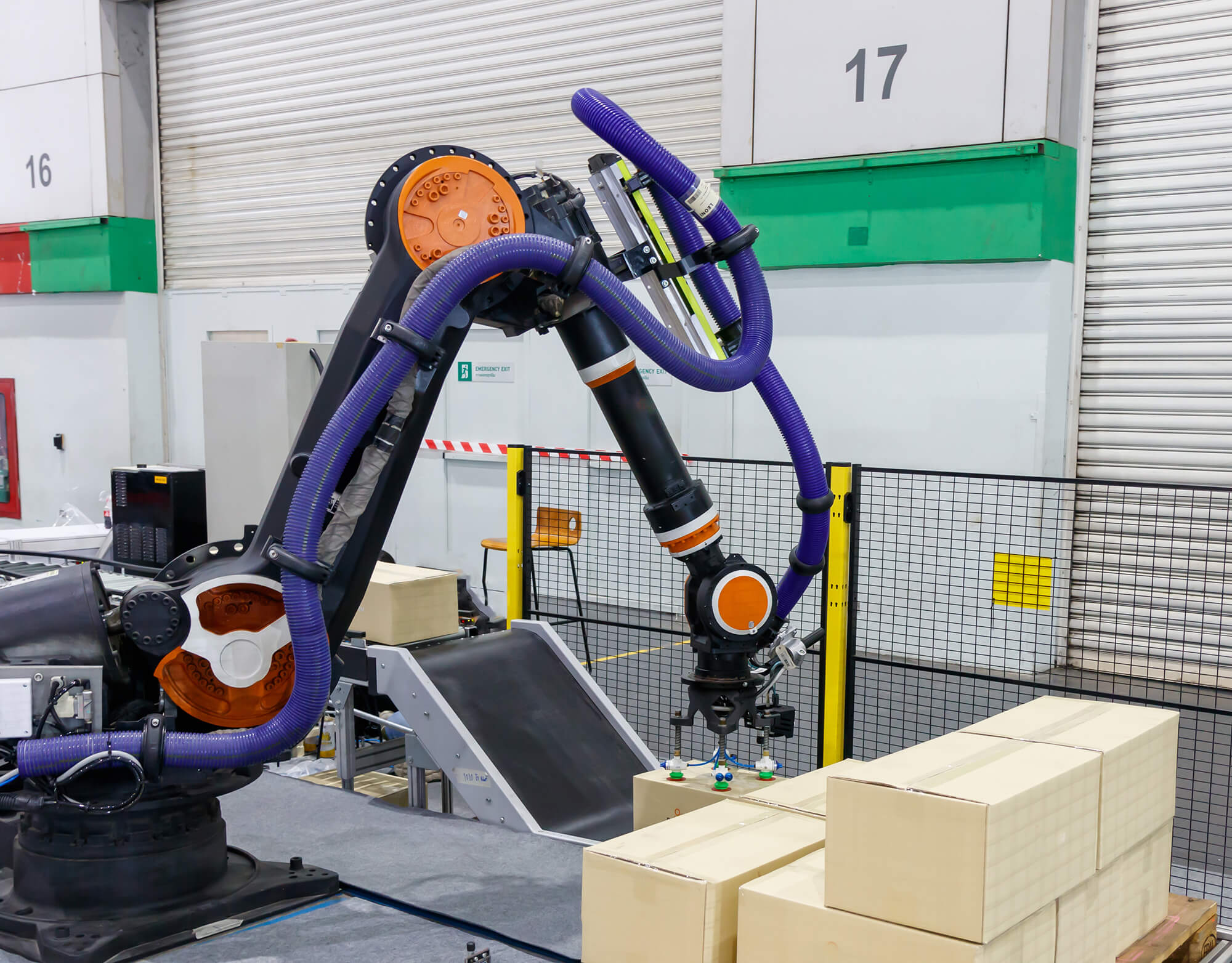

Responding to this critically widening gap, our customer developed a next-gen automated depalletizing solution that efficiently processes large and diverse parcel loads. Their solution combines the superhuman strength of an industrial robotic arm with the lightning-quick decision making of a machine learning model to dexterously and accurately unload boxes from a pallet. A 3D-vision sensor feeds information to a neural net which identifies unique boxes in a pallet – differentiating between boxes of varying weights, shapes, colors, and materials on the same pallet. The machine learning model further guides the robot to pick each parcel in precisely the right way to minimize droppage, and move it to the next stage in the logistics pipeline.

The Challenge: New Complexity Brings New Edge Cases

This highly dynamic task introduced new challenges. To be viable as a new competitive offering in the market, the robotic depalletizer needed to not only pick diverse parcels accurately, it needed to do so more efficiently, safer, and with greater throughput than a human. This was often hard to achieve. Boxes with problematic surfaces – from varying textures to shiny or reflecting material, protruding tapes, patterns, or pictures – can easily confuse machine learning models. Due to the endless variety of parcels, it’s extremely challenging to train a model for every potential scenario. This “edge case” problem presented a major commercialization roadblock. Prior to SparkAI, the only mitigation was to have on-site human operators intervene anytime the robot struggled. This was unappealing for two reasons:

- Throughput – Pausing the robot to call for on-site human intervention could take minutes per event. Even if these moments of intervention were rare, in an industry where seconds count, the blended throughput of the robotic solution would have been well below the necessary threshold for commercialization.

- Cost – Staffing on-site human operators 24/7 just to tend to a robot in in the event of an intervention was needed was prohibitively expensive and defeated the purpose of the robotic solution entirely.

Either the solution always worked, or it didn’t. These issues challenged the market viability of our customer’s depalletizer solution and made it difficult for their warehouse customers to buy.

“SparkAI helped us take a product that we weren’t sure we could launch, and got us to a commercially viable product that we knew we could absolutely launch. We would not have let this product go live without SparkAI.”Head of Robotic Engineering at Robotics OEM

The Solution:Real-Time Edge Case Resolution with SparkAI

SparkAI solves the edge case challenge for mixed SKU depalletizing through a fusion of human input and proprietary technology, in real-time. In moments of confusion, the robot instantly calls SparkAI. Imagery and accompanying metadata are sent to SparkAI via API. Once received, imagery is automatically enhanced and prepared for rapid human review by an ML pre-processor. At SparkAI, trained human mission specialists, enabled by ML-powered decision tools, review the image and identify vertices and potential pick points of the otherwise confusing boxes in the pallet. This resolution is delivered directly back to the robot, enabling it to make a confident and accurate picking decision.

“The really beautiful thing is that it requires no intervention from a human on the factory floor and the logistics for the robot are nearly uninterrupted. So from a throughput standpoint, it is just running beautifully. It is really the missing key that we were looking for.”Vice President of Robotics Division at Robotics OEM

The entire round-trip process takes seconds and happens hundreds of times per day per robot, 24/7. Even through unpredictable demand fluctuation and moments of high activity (1000+ simultaneous API calls per hour).

The Results:a $3.7 billion market opportunity unlocked

The competition to solve robotic depalletizing is fierce. SparkAI’s delivery of human cognition in discrete units, cost effectively, and in real-time was the critical component that unlocked market viability of our customer’s depalletizing solution. With edge cases solved, our customer was able to outperform competitors and capture share of this $3.7 billion market fast.

SparkAI’s lightweight API/SDK also enabled a speedy implementation in days with minimal engineering required, allowing our customer to keep resources focused on ongoing, high-value development.

Our customer now has a valuable product in market that operates uninterrupted, in dynamic environments, at all hours of the day.

“Nobody does what Spark AI does. We were incredibly impressed with their knowledge of the problem and the intimacy with which they understood it. That made it clear that this was really the only partner we would ever want to work with.”Vice President of Robotics Division at Robotics OEM